Deutsches Institut Fur Normung E. The cover flanges are drilled and tapped to be fitted with the respective light fitting in case of ordering the complete VETROLUX unit. Based upon these standard thicknesses, distortion free location of the sightglass is guaranteed provided of course that the welding flange has been correctly welded into or onto the vessel Continue.

FOR PRESSURE RATINGS FROM PN 2. Para dimensiones superiores, consúltenos. En base a estos espesores estándar, se garantiza la ubicación libre de distorsión de la mirilla siempre que el relleno de soldadura se haya soldado correctamente en o sobre la pared del recipiente. Asistencia telefónica Para obtener ayuda con su puerto de visión de reborde de soldadura circular L. Star, comuníquese con su representante local o con la fábrica.

Para responder a sus preguntas de modo rápido y completo, tenga a mano la información siguiente. Albert Einstein, 5 Nau 1 Pol. Wipers as shown in photo are optional. You will find wipers on the website under Accessories.

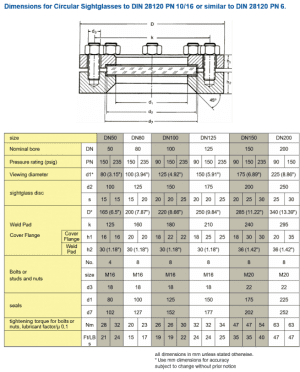

Suitable for circular sight glass assemblies nominal size DN 1… DN 200. El respeto de las prescripciones DIN para el grosos de la brida garantiza una localización sin distorsiones del disco de la mirilla si la soldadura es correcta. The load-bearing capacity the built-in.

The sightglasses contain two independent glass discs built into an. Current The latest, up-to-date edition. Protection class: Dust-tight and water jet-proof, IP and IP acc.

Operating pressure of bar and (and bar on request). Tank sight glasses type 3are either welded onto or into the tank wall. Desde DNa DN125. Deben utilizarse patas de montaje rectas tipo PR.

Only lighting from DINto DIN125. Se pueden utilizar en cualquier industria farmacéutica o de procesamiento de alimentos. Diseño estándar miniVISION se entrega en dos versiones: Tipo y tipo 70. Circular sight glasses with case in main power connection.

Process Lighting and Visual Control Systems. Download the datasheet. Application: Weld-on sight glass, fittings for the observation of the internals of pressure vessels, silos, gear-trains, separators, pipelines etc.

The respect of the DIN prescriptions for the flange thicknesses guarantees a distortion free location of the sight glass disc in case of correct welding. AD-W- cover flange made of stainless steel 1. Application: For illuminating the interior of tanks, hoppers, silos, agitators and other, usually close vessels and reactors as well as visual flow indicators.

Recommended for use in the food processing. This sightglass fitting comes standard with all seals and mounting hardware included. The sight glass is engineered with a welding nozzle that is welded onto the tank wall, a grooved collar nut, a glass disc and two gaskets.

The sight glass comes in sizes from DN(with a free view of mm) to DN1(with a free view of 1mm). Application: Observation and illumination of the interior of enclosed vessels (cauldrons, tanks, silos etc.). Obrazac za kontakt.

Sight glass fittings acc. Flange thicknesses dimensioned according to this standard ensure the distortion-free positioning of the sight glass disk, provided the block flange is properly welded onto or into the wall of the vessel. Please formulate your needs already when demanding our quotation. Flanschfassung zum Ein- oder Aufschweißen komplettiert mit Dichtungen, Schauglasplatte und Schraubverbindungen.

Print PDF Save as PDF Inquiry. Tämä hyvin yleisesti käytetty asetelma koostuu hitsattavasta runkolaipasta ja siihen liitettävistä varusteista,lasi,tiivisteet ja vaarnat sekä mutterit.

Käyttökohteita on laajalti erilaisessa prosessiteollisuudessa, esim reaktorit,säiliöt,suodattimet jne.

No hay comentarios.:

Publicar un comentario

Nota: sólo los miembros de este blog pueden publicar comentarios.